Reliable Solutions for Meat Processing Hygiene

We design practical, easy-to-use products that help reduce contamination risks during animal processing. Our goal is to support abattoirs of all sizes with safe and dependable solutions.

Beyond Contamination Control

In addition to hygiene products, we offer complete plastic manufacturing capabilities to deliver tailor-made solutions for diverse industries.

Product Design & DFM Support

Collaborative CAD refinement, DFM reviews, draft/fillet optimization, gate/vent planning, wall-thickness and tolerance analysis, material selection, and Moldflow-guided risk reduction. We help you avoid warp, sink, and snap-fit failures before steel is cut.

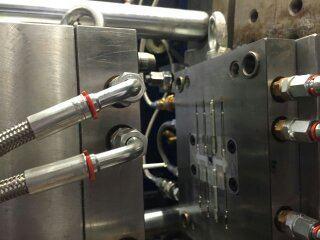

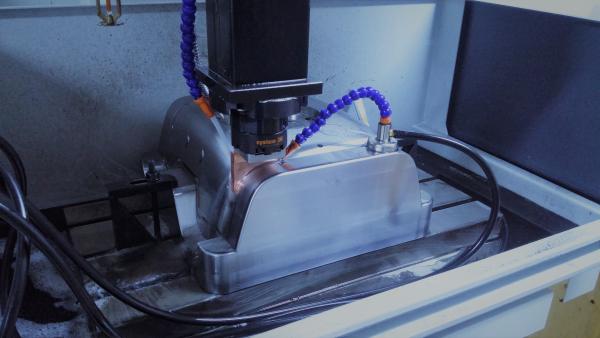

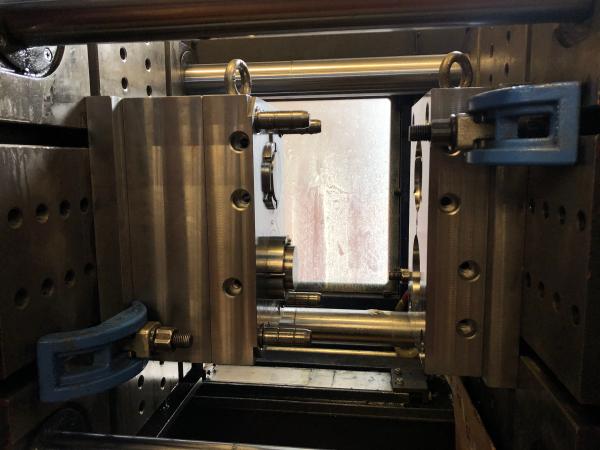

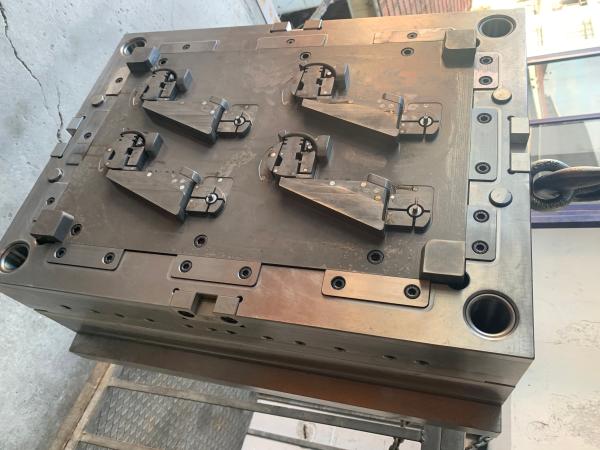

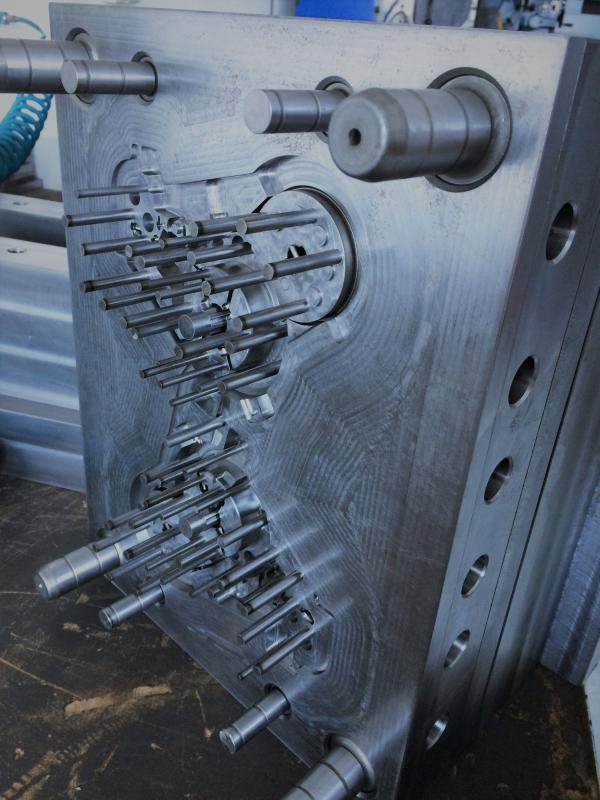

Tooling & Mold Manufacture

Prototype, bridge, and full production molds in aluminum or steel. CNC/EDM machining, hardened components, hot/cold runner systems, and preventative maintenance plans. We also perform engineering changes and rapid repairs to keep parts flowing.

Injection Molding

We offer flexible and high-precision plastic injection molding services tailored to a wide range of applications. From low to high production volumes, our capabilities ensure consistent quality, durability, and efficiency. With advanced tooling and expert engineering support, we deliver cost-effective solutions that bring your product designs to life.

Finishing, Assembly & Value-Add

Ultrasonic welding, pad printing, laser marking, CNC trimming, tapping, heat-staking, kitting, light assembly, and custom packaging. Final inspection with full traceability so your parts arrive line-ready.

Hear From Our Customers

Feedback from the companies we work with. Discover their experiences and contact to discuss how we can support your next project.

They guided us through the tooling stage with patience and clear updates. The first production run went smoothly.